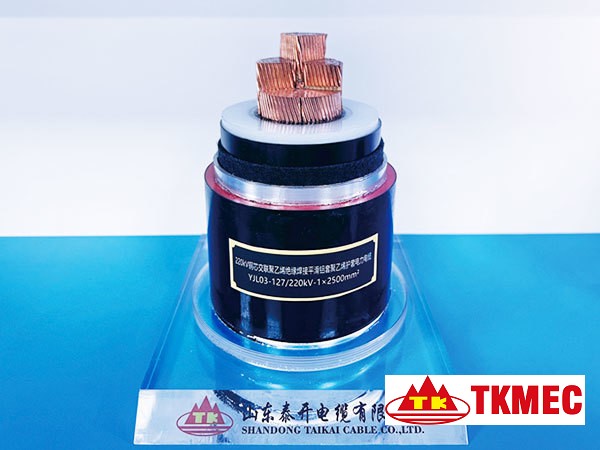

Cable structure

1. Conductive wire core (800mm ² The following cross-sectional conductors are compact circular, 800mm ² The above cross-sectional conductor is a segmented conductor structure, 800mm ² The conductor can adopt a compact circular or segmented conductor structure);

2. Conductor shielding layer (including semi conductive tape layer);

3. Crosslinked polyethylene insulation layer;

4. Insulation shielding layer;

5. Longitudinal water blocking buffer layer;

6. Wrinkled aluminum sheath (with anti-corrosion coating on the outer surface);

7. Polyethylene or polyvinyl chloride outer protective layer and semi conductive layer (coated or extruded).

Usage characteristics and usage environment

1. The maximum working temperature of the conductor is 90 ℃, and the maximum temperature of the conductor during a short circuit (maximum duration not exceeding 5 seconds) does not exceed 250 ℃.

2. The maximum allowable lateral pressure of the cable is 5kN/m.

3. Maximum allowable traction strength of conductor: copper conductor 70N/mm ²; Aluminum conductor 40N/mm ²。

4. The ambient temperature for cable laying shall not be lower than 0 ℃, and the minimum bending radius shall not be less than 20 times the outer diameter of the cable.

5. PVC outer sheath cables are mainly suitable for cable lines with general fire protection requirements and certain insulation requirements for the outer sheath. PE outer sheath cables are mainly suitable for directly buried cable lines with high requirements for outer sheath insulation, which are relatively damp, and when there is a low toxicity requirement for gases generated during combustion.

Manufacture Time: 2~8 weeks

Pre sales consulting specialist

Pre sales consulting specialist